Product Description

SPARE PARTS DA1170.1-13 Planetary gear 275100142 FOR XCMG

Other products of XCMG

About HongJun

Hongjun Group(HK) Co.,ltd .start its business from 2571.We work mainly for heavy construction machinery and heavy truck duty truck!With its goal of”One-stop service for all your spare parts request!Keep you machine working!”Hongjun established relationship with hundreds of excellent factories to ensure one-stopservice for our customers!

Hongjun works mainly for heave construction machinery and heave duty truck!With its rich experience in this field .CHINAMFG can supply all spare parts for the known brands such like Foton, Sinotruk, Shacman, Xihu (West Lake) Dis.feng, JAC,FOTON,FAW,CAMC…

All our sub-suppliers went through a rigorous process of selection to make sure high quality! CHINAMFG Group Co., Ltd. Makes sure all its sub-suppliers have qualifed necessary certificates like ISO9001, CCC,ce, ect.

Our main products include complete auto parts such as cabin parts, body parts, engine parts, gearbox parts and chassis parts etc.

We have been working in this field for nearly 20 years and has very high reputation in domestic China market and also in oversea market! Now our products have been successfully exported to Asia, Africa, South America, Middle Eastand many other countries. We sincerely look CHINAMFG to cooperate with you and be very happy to work with customers from all over the world!

Who we are?

The most professional truck and spare parts manufacturer in China;

The most comprehensive truck and spare parts solution provider in China;

The most worry-free and most satisfactory and reputable supplier for you in China.

We can never let you down if you choose us.

Our Services:

1.All of our products are with professional service.

2. We can offer free consultation of service information .

3.The dominance we kept all along is to provide the customers with genuine spare parts.

4. Professional sales and after sale service team, timely and efficiently to solve your problem.

5.We are willing to privide the High Quality,ReasonablePrice and Perfect Service.

FAQ

(1)What about your packing?

We will use the original packaging of the goods,but of course ,we can also customize it.

(2)What about your terms of payment?

L/C, T/T, D/P, Western Union, Paypal Money Gram, Others

(3)What is your terms of delivery?

FOB,CFR,CIF

(4)How about your delivery time?

It depends on the items and quantities of your order.

| After-sales Service: | Yes |

|---|---|

| Warranty: | Yes |

| Type: | Planetary Gear |

| Application: | Loaer Engine |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

What are the advantages of using planetary gears in various mechanical setups?

Planetary gears offer several advantages that make them a popular choice in various mechanical setups. Let’s explore some of these advantages:

- Compact Size:

One key advantage of planetary gears is their compact size. The arrangement of multiple gears within a single housing allows for a high gear reduction ratio in a relatively small space. This compactness is particularly beneficial in applications where space is limited, such as automotive transmissions, robotics, and aerospace systems.

- High Torque Density:

Planetary gears provide high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This makes them suitable for applications requiring high torque transmission, such as heavy machinery, industrial equipment, and automotive drivetrains.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The multiple gear engagements and the distribution of load among the gears result in reduced friction and minimal power loss. This efficient power transmission ensures that a substantial portion of the input power is effectively transmitted to the output, leading to improved overall system efficiency.

- Multiple Gear Ratios:

Another advantage of planetary gears is their ability to achieve multiple gear ratios within a single gear system. By varying the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained. This flexibility allows for adapting to various speed and torque requirements without the need for additional gear sets or complex mechanisms.

- Shock Absorption:

Planetary gears have a natural ability to absorb shock loads and distribute them across multiple gear teeth. The multiple gear engagements and the design characteristics of planetary gears help mitigate shocks and impacts, preventing damage to the gear system and the connected components. This makes them suitable for applications that involve sudden changes in load or intermittent operation.

- Precise Motion Control:

Due to their design, planetary gears offer precise motion control. The combination of rotational and orbital movements of the planet gears allows for smooth and accurate motion transmission. This feature is particularly useful in applications requiring precise positioning, such as robotics, automation systems, and medical equipment.

In summary, the advantages of using planetary gears in various mechanical setups include compact size, high torque density, efficient power transmission, multiple gear ratios, shock absorption, and precise motion control. These advantages make planetary gears well-suited for a wide range of applications across industries, offering reliability, efficiency, and versatility.

How do planetary gears handle variations in tooth engagement during operation?

Planetary gears are designed to handle variations in tooth engagement during operation, ensuring smooth and reliable performance. Let’s explore how planetary gears address these variations:

- Tolerance for Misalignment:

Planetary gears are designed with a certain degree of tolerance for misalignment. This means that slight variations in tooth engagement due to manufacturing tolerances, assembly, or operating conditions are accommodated without causing significant impact on the gear system. The gear teeth are carefully designed with appropriate profiles, clearances, and backlash to allow for some degree of misalignment while maintaining proper functioning.

- Load Distribution:

The arrangement of multiple planet gears in a planetary gear system helps distribute the load across multiple gear teeth. Each planet gear shares the load with the adjacent gears, reducing the stress on individual teeth and promoting even tooth engagement. This load distribution capability helps minimize localized wear, noise, and vibration, resulting in smoother and more efficient operation.

- Flexible Mounting and Support:

Planetary gears are often mounted on flexible support structures, such as bearings or flexible couplings. These components help absorb and compensate for small variations in tooth engagement during operation. The flexible mounting and support systems provide some degree of flexibility and compliance, allowing the gears to self-adjust and maintain proper tooth contact under varying operating conditions.

- Lubrication and Cooling:

Proper lubrication and cooling play a crucial role in handling variations in tooth engagement. Lubricants reduce friction and wear between gear teeth, ensuring smooth operation and minimizing the impact of tooth engagement variations. Additionally, effective cooling mechanisms help dissipate heat generated during operation, preventing excessive temperature rise that could affect the gear meshing performance.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques. This robust construction enhances the gear system’s ability to withstand variations in tooth engagement. By ensuring high-quality gear components, proper heat treatment, and stringent quality control, planetary gears are built to handle the dynamic loads and variations encountered during operation.

In summary, planetary gears handle variations in tooth engagement through their tolerance for misalignment, load distribution among multiple planet gears, flexible mounting and support, effective lubrication and cooling, and robust construction. These design considerations and features enable planetary gears to maintain proper tooth contact, minimize wear and noise, and ensure reliable performance in various applications, including automotive transmissions, industrial machinery, and power transmission systems.

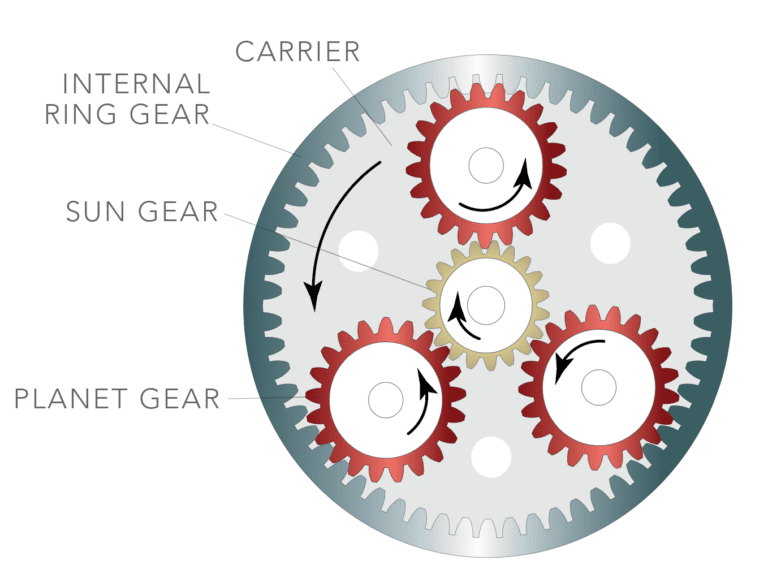

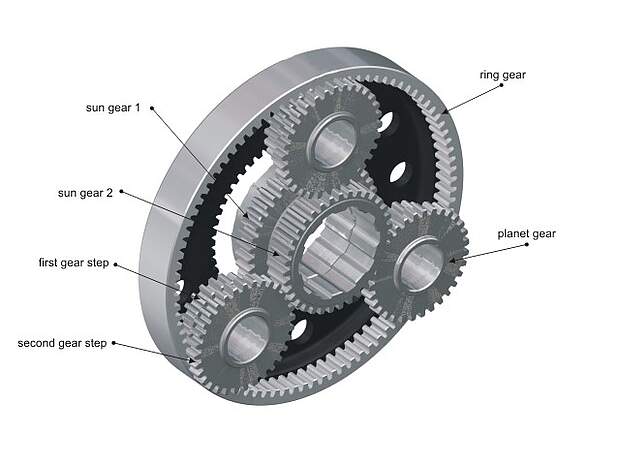

What is a planetary gear and how does it work in mechanical systems?

A planetary gear, also known as an epicyclic gear, is a type of gear system used in mechanical systems to achieve various gear ratios and torque transmission. Let’s explore what a planetary gear is and how it works:

- Definition:

A planetary gear consists of three main components: a sun gear, planet gears, and a ring gear. The sun gear is located at the center and is typically driven by an input source, such as a motor or engine. The planet gears are gears that surround the sun gear and are connected to a carrier or arm. The ring gear is the outermost gear and meshes with the planet gears.

- Operation:

When the sun gear rotates, it drives the planet gears, causing them to rotate on their own axes while also orbiting around the sun gear. The planet gears are mounted on the carrier, which can rotate independently or be held stationary. As the planet gears rotate and orbit, they engage with the ring gear, which remains fixed or acts as the output. This interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and torque transmission.

- Gear Ratios:

A key advantage of planetary gears is their ability to achieve multiple gear ratios within a compact design. By varying the number of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained. The gear ratio is determined by the ratio of the number of teeth between the sun gear and the ring gear, as well as the speed and direction of rotation of the sun gear.

- Applications:

Planetary gears are widely used in various mechanical systems and applications where precise control of speed, torque, and direction is required. They are commonly found in automotive transmissions, robotics, aerospace systems, industrial machinery, and more. Their compact size, high gear ratios, and torque-carrying capacity make them versatile and efficient in transmitting power.

In summary, a planetary gear is a gear system consisting of a sun gear, planet gears, and a ring gear. It operates by the rotation and orbiting of the planet gears around the sun gear, allowing for different gear ratios and torque transmission. Planetary gears find applications in a wide range of mechanical systems where precise control and efficient power transmission are necessary.

editor by CX 2023-10-20